Table of Contents

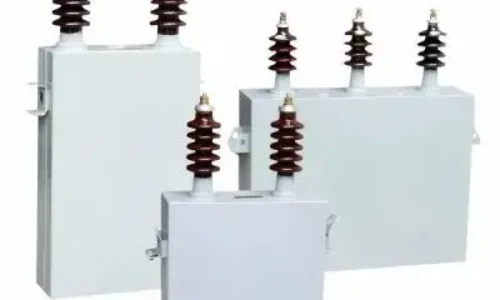

The Mystery Behind the power capacitor failure

When a power capacitor fails, the immediate question is always, “Why?” Pinpointing the single “most common” reason is a bit like asking what causes a car to break down. Is it the bad road, the driver, or the engine? Usually, it’s a mix. But if you spend enough time looking at charred panels and reading maintenance logs, a few usual suspects start to stand out. It isn’t always bad luck or a faulty product. More often than not, the environment killed it.

1. The Silent Killer: Excessive Heat

It is, without a doubt, the most pervasive enemy of electrical components. The thing about power capacitor is that they are surprisingly sensitive to temperature changes. They might look like rugged metal cans, but the dielectric material inside—the stuff that actually stores the energy—degrades rapidly when things get toasty.

There is a widely accepted rule of thumb in the industry, often derived from the Arrhenius equation, which suggests that for every 10°C increase in operating temperature above the rated limit, the lifespan of a power capacitor is cut in half. That is a brutal statistic.

Think about where these things live. They are often stuffed into steel cabinets, tucked in the corner of a factory floor that doesn’t have air conditioning, or mounted right next to a transformer that is radiating heat like a radiator. If the ventilation fans in the cabinet fail—which they often do because nobody checks them—the internal temperature climbs. The capacitor can’t dissipate its own internal heat, and the dielectric film starts to break down. It eventually dries out or suffers a dielectric puncture, and that is the end of the line. It’s a slow, quiet death that usually ends in a loud failure.

2. The Invisible Assassin: Voltage Stress and Transients

While heat is a slow killer, voltage issues are more like an assassin. A standard three phase capacitor is designed to handle a specific voltage, say 480V. It can handle a little bit of wiggle room, maybe 110% for short periods, but the grid is rarely that stable.

Transients are those invisible, lightning-fast spikes in voltage. They happen when a large motor on the same network shuts off, or when the utility company switches capacitor banks on the grid, or even from actual lightning strikes nearby. These spikes can punch right through the dielectric insulation.

Imagine the insulation inside the capacitor like a sheet of drywall. You can lean on it (steady voltage) and it’s fine. But if you hit it with a sledgehammer (voltage spike), you punch a hole. Once that hole is there, the electricity arcs through it. Sometimes the three phase capacitor can “heal” itself if it’s a metallized film type, burning away the area around the fault. But do that enough times, and you lose too much capacitance. Eventually, the self-healing mechanism can’t keep up, the pressure builds, and the safety valve pops. Or worse, it doesn’t pop fast enough.

3. The Modern Plague: Harmonics

This is the reason that is climbing the charts rapidly. Twenty or thirty years ago, electrical loads were simpler. You had motors, lights, and heaters. Linear loads. Today, facilities are packed with Variable Frequency Drives (VFDs), soft starters, LED drivers, and computers. These devices sip power in gulps rather than a smooth stream, creating what we call harmonic distortion.

Harmonics are essentially electrical pollution. They introduce higher frequencies into the lines. The problem is that a power capacitor’s impedance drops as frequency goes up. In plain English, this means the capacitor becomes a magnet for these high-frequency currents. It tries to suck them all up.

It ends up carrying way more current than it was designed for. You might measure the amps on the 60Hz fundamental frequency and think everything is fine, but if you looked at the total RMS current including harmonics, that poor can is cooking. It causes internal overheating that you can’t see from the outside until it’s too late. It’s a classic case of the component doing its job too well, absorbing the system’s “trash” until it dies from the effort.

4. Manufacturing Quality and "Infant Mortality"

We shouldn’t ignore the hardware itself. Sometimes, you just get a bad batch. In the world of reliability engineering, this is often referred to as “infant mortality.” If a power capacitor is going to fail due to a manufacturing defect—like a tiny air bubble in the potting compound or a microscopic flaw in the film—it will usually happen quickly, often within the first few weeks or months of operation.

If the equipment has been running smoothly for five years and then fails, it almost certainly isn’t a manufacturing defect. But if you install a brand new bank and one unit pops three days later while the others are fine, it’s likely a quality control issue. Cheaply made capacitors might cut corners on the thickness of the dielectric or the quality of the oil, making them far more susceptible to the heat and voltage issues mentioned earlier. It’s the classic “you get what you pay for” scenario.

So, Which Is the Most Common reason of power capacitor failure?

Short answer

- If a technician must pick one cause, it’s usually the combination of heat and harmonics.

How heat and harmonics interact

- Harmonics from nonlinear loads increase RMS current and generate extra internal heating.

- The result is a feedback loop: more heat → greater dielectric stress → increased susceptibility to further heating and transients.

Typical indicators you might observe

- Elevated case or oil temperature and repeated temperature excursions.

- Rising ESR/leakage current and gradual capacitance loss.

- High total harmonic distortion (THD) on the supply and localized hot spots.

- Occasional failures triggered by minor voltage surges.

Failure progression

- Years of thermal stress gradually weaken insulation and dielectric.

- Harmonic heating accelerates aging and creates hotspots.

- A transient or surge becomes the final trigger that causes breakdown.

The Final Takeaway

Understanding why a power capacitor fails is the first step in stopping it from happening again. It’s easy to just swap out the dead unit and flip the breaker back on. But if you don’t address the root cause—whether it’s fixing the cabinet fans, installing harmonic reactors, or adding surge protection—you are just setting a timer for the next failure. These components are tough, but they aren’t invincible. They need cool air and clean power, and if you can give them that, they will quietly do their job for years.