In the field of power quality, safety, precision, and reliability are the core principles of reactive power compensation systems. As a globally recognized manufacturer of capacitors and power quality solutions, ZHIMING Group deeply understands the severe challenge that inrush current during low voltage capacitor switching poses to system longevity and stability.

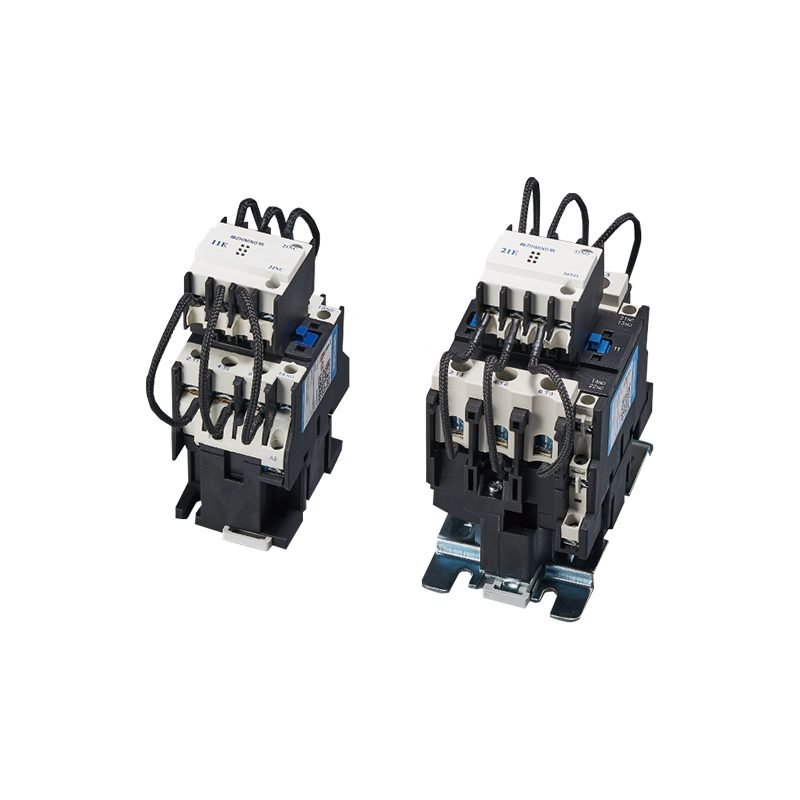

Our Low Voltage Capacitor Contactor, specifically designed for low voltage reactive power compensation, is your powerful tool to meet this challenge. It is not merely a circuit switch but a safety guardian for the entire compensation equipment. Leveraging its profound technical expertise, ZHIMING provides a comprehensive range of high-performance Capacitor Duty Contactors, ensuring your power factor correction system operates with smooth switching, long service life, and high efficiency.

What is a Low Voltage Capacitor Contactor?

A Low Voltage Capacitor Contactor is a specialized electrical switching device designed exclusively for making and breaking the circuits of low voltage shunt capacitors. It is fundamentally different from a standard contactor, as it is specifically reinforced to address the core issue of extremely high inrush current (which can be tens of times the rated current or higher) generated the moment a capacitor is connected to the power grid.

Core Benefits of Low Voltage Capacitor Contactor

The core value delivered by using ZHIMING Low Voltage Capacitor Contactors:

-

Comprehensive System Protection

Protects Capacitors: Effectively suppresses the impact of inrush current on capacitor electrodes and dielectric, preventing premature capacitor failure and significantly extending its service life.

-

Protects the Contactor Itself

Prevents main contacts from welding or erosion due to inrush current, ensuring its electrical and mechanical longevity.

-

Protects the Entire System

Suppresses switching overvoltages and reduces interference to other sensitive equipment in the grid, enhancing overall power quality.

-

Exceptional Operational Economy

Reduces Maintenance Costs: The extended lifespan of key components (capacitors, contactors) directly reduces the frequency of spare part replacements and system downtime.

Improves Energy Efficiency: By ensuring reliable switching of capacitor banks, it helps maintain a high power factor, reducing line losses caused by reactive power, thus saving electrical energy.

-

Enhanced System Reliability

The smooth switching process avoids severe voltage fluctuations on the grid, providing a guarantee for continuous production processes and stable power supply.

Application Scenarios

ZHIMING Low Voltage Capacitor Contactors are the essential choice for numerous scenarios requiring low voltage reactive power compensation. Typical application fields include:

-

Industrial Manufacturing

Widely used in workshop distribution systems across industries like automotive, metallurgy, chemicals, and machinery, for switching capacitors that compensate for reactive power demanded by large motors, welding machines, VFDs, and other inductive loads.

-

Commercial and Public Buildings

Installed in the power factor correction panels of distribution rooms in office buildings, shopping malls, hospitals, and schools, controlling capacitor banks to compensate for reactive power generated by central air conditioning, pumps, elevators, and lighting systems.

-

New Energy Sector

Applied in low voltage grid-connection systems of photovoltaic and wind power plants for necessary reactive power regulation and compensation.

-

Infrastructure

Used in locations with extremely high demands for power supply continuity, such as rail transit, data centers, ports, and airports, ensuring precise and reliable reactive power compensation.

-

Other Fields

Any location equipped with a low voltage power factor correction system requires the use of a capacitor switching contactor to switch shunt capacitors.

Advantages & Technical Highlights of Low Voltage Capacitor Contactors

ZHIMING Group ensures its Low Voltage Capacitor Contactors lead in performance through continuous technological innovation and rigorous testing:

-

Advanced Inrush Current Suppression Technology

Utilizes a resistor pre-charging mechanism or auxiliary contact pre-making system, effectively limiting the inrush current to below 20 times the rated current, with some models achieving even lower levels, far superior to the tens to hundreds of times impact that standard contactors might endure.

-

Robust Contact and Arc Quenching System

Main contacts are made of silver alloy material with excellent anti-welding properties, ensuring good contact even under high-frequency switching.

A well-designed arc quenching system (e.g., slit-type ceramic arc chute) quickly extinguishes the breaking arc, protecting the contacts.

-

Strong Electrical and Mechanical Performance

Rated operational voltage covers up to 690V, suitable for various global low voltage distribution systems.

Mechanical lifespan reaches several hundred thousand operations. Electrical lifespan (for AC-6b utilization category) can reach tens of thousands to hundreds of thousands of operations, meeting the demands of automated systems requiring frequent switching.

Coils with wide voltage design adapt to fluctuating control voltages.

-

Stringent Safety and Quality Standards

Product design complies with international and national standards such as GB/T 14048.4 and IEC/EN 60947-4-1.

Possesses comprehensive safety certifications (e.g., CE), ensuring compliance and safety for global markets.

FAQ

Q1: Can a standard AC contactor replace a Low Voltage Capacitor Contactor?

A1: Absolutely not. The fundamental reason lies in the residual charge stored in capacitors after de-energization, which leads to a high inrush current upon re-energization. Standard contactors cannot withstand this repeated current surge and will fail quickly, potentially causing safety incidents. The unique inrush current suppression mechanism inside a Low Voltage Capacitor Contactor is specifically designed to handle this issue.

Q2: How do I select the right capacity capacitor contactor for my compensation panel?

A2: The selection is primarily based on two parameters: the rated current of the capacitor bank it controls and the compensation step size (single bank capacitor capacity in kvar). The basic principle is that the capacitor contactor’s rated current should be greater than or equal to the capacitor bank’s rated current, with consideration for a safety margin. ZHIMING offers a complete series from tens to hundreds of Amps, covering a wide range of controllable capacitor capacities. Our technical team can provide free selection support.

Q3: What voltage levels and frequencies are ZHIMING low voltage capacitor contactors suitable for?

A3: Our Low Voltage Capacitor Contactors are suitable for use in AC 50Hz (or 60Hz) power lines with rated operational voltages up to 690V, meeting the low voltage distribution requirements in most regions worldwide.

Q4: What should be noted when using capacitor contactors in environments with harmonics?

A4: When significant harmonics (especially 5th, 7th, etc.) are present in the grid, it is recommended to series connect a reactor with an appropriate reactance ratio in the capacitor circuit to form a detuned filter circuit. This avoids resonance between the capacitor and system impedance, which can lead to harmonic amplification, thereby protecting both the capacitor and the contactor from damage.