In modern power systems, power quality and energy efficiency management have become crucial for enterprises to reduce operational costs and enhance competitiveness.

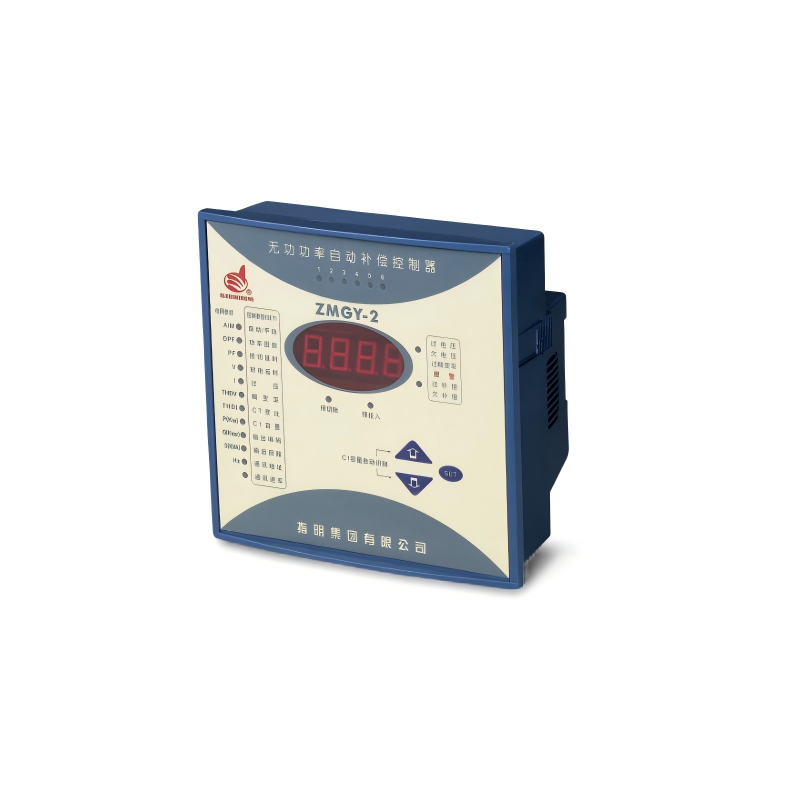

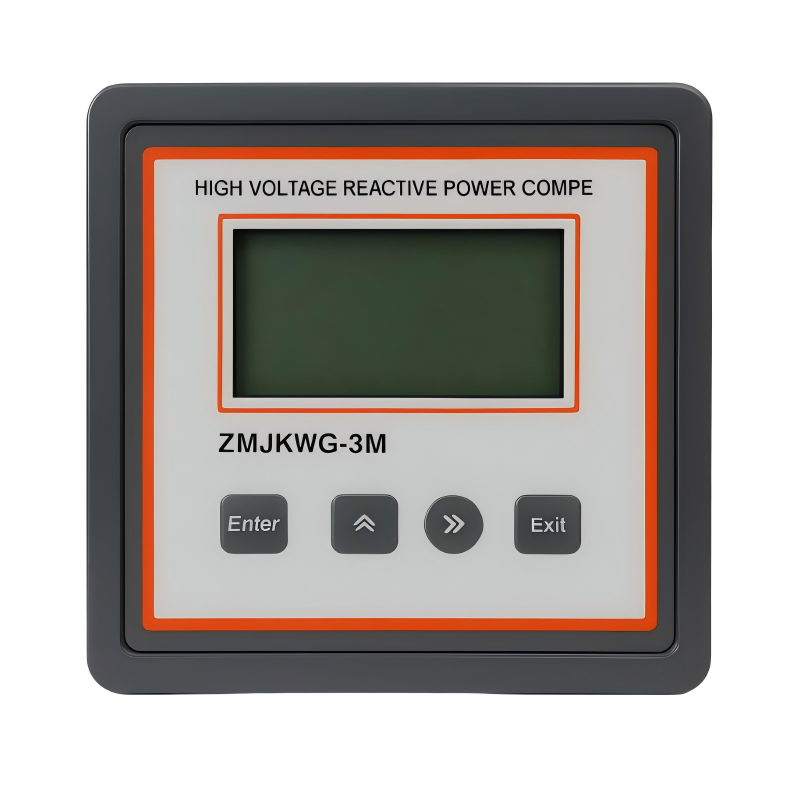

As a globally leading manufacturer of power quality solutions, ZHIMING Group deeply understands the significant impact of reactive power on grid stability, energy efficiency, and equipment lifespan. Our Reactive Power Compensation Controller product series serves as the “intelligent brain” of smart distribution systems, specifically designed for precise and efficient management of reactive power.

Adhering to the philosophy of “Precise Control, Intelligent Energy Saving,” ZHIMING integrates advanced algorithms with reliable hardware, committed to providing comprehensive reactive power compensation solutions for industrial, commercial, and power sector clients.

What is a Reactive Power Compensation Controller?

A Reactive Power Compensation Controller is a sophisticated electronic device that automatically monitors power system operating parameters and intelligently controls the switching of capacitor banks (or reactor banks) to achieve dynamic reactive power compensation.

Benefits of ZHIMING Reactive Power Compensation Controllers

The core value delivered by using ZHIMING Reactive Power Compensation Controllers:

1. Significant Economic Benefits

Improves Power Factor, Avoids Penalties: By stabilizing the system power factor to meet utility requirements (typically ≥0.95), it effectively avoids extra charges on electricity bills due to low power factor.

2. Reduces Line Losses, Saves Energy

Post-compensation reduces reactive current in the lines. According to the formula P=I²R, it significantly lowers copper and iron losses in transformers and lines, directly saving electricity costs, with potential line loss reduction up to 30%-50%.

3. Releases Transformer Capacity, Saves on Upgrade Costs

Reducing the system’s required reactive power effectively increases the transformer’s load-bearing capacity, delaying or avoiding investment in equipment upgrades.

4. Enhanced System Safety and Reliability

- Stabilizes Grid Voltage: Rapid reactive power compensation suppresses voltage fluctuations and flicker caused by drastic load changes, protecting sensitive equipment.

- Protects Electrical Equipment: A stable voltage environment helps extend the service life of major electrical equipment like motors and transformers, reducing downtime due to voltage issues.

5. Intelligent Management and Operation

Enables Automated Operation: Requires no manual intervention; the controller automatically performs real-time compensation based on load variations, greatly reducing operational workload.

6. Supports Data Monitoring and Communication

Provides rich power parameter display and features like RS485 communication interface, supporting protocols like MODBUS-RTU. This allows easy integration into energy management systems, providing a data foundation for digital and intelligent energy efficiency management.

Application Scenarios

ZHIMING Reactive Power Compensation Controllers, known for their exceptional adaptability and control precision, are widely used in the following fields with high demands for power quality:

1. Industrial Manufacturing

Reactive power compensation controllers can be applied in distribution systems of metallurgy, steel, chemicals, automotive manufacturing, cement, and other industries to compensate for the substantial reactive power demand from large motors, welding machines, arc furnaces, compressors, and other inductive loads, ensuring voltage stability and efficient production line operation.

2. Commercial and Public Buildings

Reactive power compensation controllers can be installed in distribution rooms of office buildings, shopping malls, hospitals, hotels, and schools to compensate for reactive power generated by mixed loads like central air conditioning, pumps, elevators, and lighting systems, achieving energy savings and enhancing electrical safety.

3. New Energy and Power Systems

Reactive power compensation controllers can be applied in booster stations and grid connection points of photovoltaic power plants and wind farms for necessary reactive power regulation to meet grid code technical requirements. Also used in substation reactive power compensation.

4. Transportation Infrastructure

Reactive power compensation controllers can be used in traction power supply systems for rail transit, electrified railways, high-speed rail, subways, and for equipment like port cranes to compensate for reactive power from impact loads and stabilize contact line voltage.

5. Data Centers and EV Charging Stations

Reactive power compensation controllers can compensate for reactive power from non-linear loads like UPS and servers in data centers; they can also compensate for reactive power demand and harmonics generated during the operation of fast-charging piles in electric vehicle charging stations, improving charging efficiency and quality.

Advantages & Technical Highlights of Reactive Power Compensation Controllers

ZHIMING Group ensures our Reactive Power Compensation Controllers maintain industry-leading performance and reliability through continuous technological innovation and stringent quality control:

1. Advanced Core Algorithms and Processing Capability

- ZHIMING reactive power compensation controller utilizes ASIC dedicated chips or high-performance ARM/MCU processors, employing FFT Fast Fourier Transform for signal analysis. This ensures accurate switching decisions based on reactive power, even in harmonic environments, preventing misjudgment due to voltage distortion.

- Supports multiple control modes, including Reactive Power (Var) Mode, Power Factor (Cos Φ) Mode, and Composite Control Mode (combining reactive current and power factor), ensuring accurate switching under both light and heavy load conditions, avoiding switching oscillation.

2. Flexible Switching Strategies and Capacitor Management

- ZHIMING reactive power compensation controller supports various strategies like Cyclic Switching, Sequential Switching, and Coded Switching, adaptable to scenarios with identical or different capacitor bank sizes.

- Capable of managing Three-Phase Common Compensation, Single-Phase Independent Compensation, and Hybrid (Common + Independent) Compensation systems, achieving the most granular reactive power regulation.

3. Strong Environmental Adaptability and Noise Immunity

- ZHIMING reactive power compensation controller features protections like Inverse Time Over-Voltage Protection, Under-Current Protection, and Over-Temperature Protection. It quickly switches off capacitors and locks out when grid parameters exceed limits, protecting equipment safety.

- High immunity to electromagnetic interference, resisting common-mode and differential-mode noise, and capable of withstanding the influence of characteristic harmonics like 3rd, 5th, 7th, ensuring stable operation in complex industrial environments.

4. User-Friendliness and Intelligence

- ZHIMING reactive power compensation controller employs a large screen dot-matrix LCD (supporting Chinese/English display) or digital tube display, showing dozens of real-time grid parameters.

- Flexible parameter settings, features, Manual/Auto mode switching, and facilitating on-site debugging and maintenance.

- Wide voltage design, suitable for global mainstream low-voltage grid systems (e.g., 220V, 380V, 440V, 690V), with 50Hz/60Hz frequency auto-adaptation.

FAQs

Q1: What are the main control modes of a reactive power compensation controller? How to choose?

A1: There are two core control modes: Reactive Power Control Mode and Power Factor Control Mode. Some advanced controllers support composite modes.

Reactive Power Mode: Uses the system’s reactive power deficit as the basis for switching, offering high compensation accuracy. Suitable for applications with large load fluctuations and strict reactive control requirements, like large industrial workshops.

Power Factor Mode: Uses the target power factor (e.g., 0.95-1.0) as the switching criterion, intuitive and easy to understand. Suitable for relatively stable loads where the primary goal is avoiding penalties, like commercial buildings.

Selection should consider load characteristics and compensation goals. ZHIMING controllers typically support multiple modes configurable on-site.

Q2: Are there special precautions regarding Current Transformers (CTs) when wiring the reactive power compensation controller?

A2: Yes, safe and correct wiring is crucial.

Polarity Requirement: The sampling current has polarity. If the power factor displays a negative value after wiring, typically reverse the sampling current wires.

CT Selection and Installation: The standard rated input current is 5A. External Current Transformers must be used for currents greater than 5A. Always short-circuit the CT secondary side before removing current input wires to prevent dangerous high voltages from an open circuit.

Phase Sequence Correspondence: Although many controllers have automatic phase sequence detection, strive to ensure the phase designation and sequence of input voltage and current correspond.

Q3: What is “switching oscillation”? How do ZHIMING reactive power compensation controllers prevent this?

A3: “Switching oscillation” refers to the frequent switching in and out of the same capacitor bank by the controller at a critical load point, damaging equipment lifespan. ZHIMING controllers effectively prevent this through several mechanisms:

Setting Switching Delay and Hysteresis: Sufficient hysteresis is set between the switch-on and switch-off thresholds (e.g., switch-off threshold is 0.02 higher than switch-on), combined with adjustable operation delay times.

Trend Judgment: Performs multi-point sampling during the operation delay period, judging based on the trend of reactive power change rather than a single sample, preventing false operations.

Composite Control: Uses parameters like power factor for auxiliary judgment at low loads, ensuring reliable switching.

Q4: Can ZHIMING reactive power compensation controllers be used in grid environments with significant harmonics?

A4: Yes. Several of our reactive power compensation controller models are specifically optimized for harmonic environments. They analyze harmonics via FFT algorithms and primarily use reactive power as the switching criterion, making them less susceptible to the effects of voltage waveform distortion caused by harmonics. Furthermore, the products themselves possess strong harmonic noise immunity and harmonic over-limit protection functions. However, in environments with very high harmonic distortion, we still recommend series connecting reactors with appropriate tuning in the capacitor circuits to form detuned filter circuits, protecting both the capacitors and the controller.