Table of Contents

A Practical Guide for B2B Power Distribution and Industrial Applications

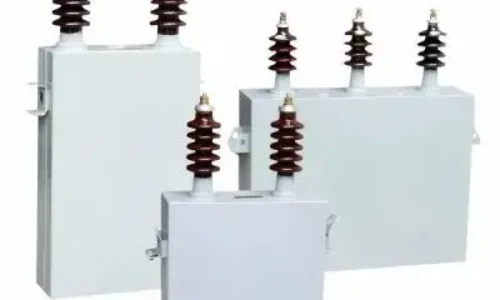

Efficient power distribution and stable electrical performance play an essential role in industrial environments such as manufacturing plants, data centers, and commercial facilities. A power capacitor helps improve reactive power compensation and stabilizes power factor performance, ensuring that the electrical system operates efficiently and safely. When a capacitor becomes faulty, the entire power network can suffer from low efficiency, overheating, and even equipment shutdowns. Therefore, knowing how to test a power capacitor is essential for maintenance teams, electrical engineers, and industrial procurement managers.

This guide explains how to evaluate a power capacitor during routine inspection and planned maintenance. The article covers visual checks, safe discharge procedures, instrument evaluation, and insulation assessment. Each step is written with a B2B mindset to ensure efficient, standardized, and reliable execution.

Why Testing a Power Capacitor Matters in B2B Operations

Capacitors installed in reactive power compensation cabinets or capacitor banks are subject to continuous electrical stress. Failures often occur without warning due to aging insulation, thermal wear, or improper installation. If a damaged power capacitor remains in operation, the electrical system may experience voltage fluctuations and unnecessary losses. Testing ensures:

- Stable power factor and optimized energy usage

- Protection of downstream electrical equipment

- Reduced maintenance cost and downtime

In B2B procurement environments, testing also helps evaluate capacitor quality during acceptance inspection and supplier audits before deployment.

Testing Steps

Before any testing begins, safety compliance is the top priority. Capacitors retain electrical energy even after disconnection, and accidental contact could lead to severe harm or equipment damage. Follow these principles:

- Disconnect the power supply completely.

- Ensure capacitor terminals are grounded.

- Wear proper PPE suitable for electrical testing environments.

Only after ensuring complete discharge should the evaluation process begin.

Step 1: Perform a Visual and Physical Inspection

The first step is simple, cost-efficient, and highly effective. A visual inspection often reveals early warning signs, especially when examining capacitors inside large power capacitor banks or reactive power compensation cabinets. Look for:

- Deformation on the casing or swelling

- Signs of leakage

- Unusual odor or discoloration

- Loose terminals or damaged wiring

To ensure that the components entering the system meet industrial quality expectations, supplier selection becomes important. A reliable power capacitor manufacturer ensures that each device undergoes strict quality inspections before leaving the production facility.

Step 2: Safely Discharge the Power Capacitor

Before connecting any test instrument, confirm that the power capacitor has been discharged. Use an appropriate discharge tool or an insulated resistor. Never short the terminals directly; improper discharge methods can damage internal elements and cause safety hazards. Once the capacitor is discharged:

- Short the terminals with an insulated conductor to prevent residual charge

- Label and isolate the unit manually or digitally for maintenance traceability

This step helps avoid personal injury and ensures the accuracy of the test results.

Step 3: Measure Capacitance Using a Multimeter

Connect the multimeter to the capacitor terminals and measure capacitance. The reading should be within the acceptable performance range stated in the specification sheet. If the test value is significantly different from the expected capacitance, the capacitor may be deteriorating internally.

Electrical maintenance teams typically flag capacitors with unstable or inconsistent readings for replacement. If unclear test results appear during maintenance, further symptoms can be identified through operational performance. For more information, see our article What are the signs of a faulty power capacitor.

Step 4: Check Insulation Resistance

Insulation resistance reflects the condition of the internal dielectric material. Weak insulation indicates internal damage and potential breakdown under high voltage. During the test, the key considerations are:

- Insulation continuity

- Absence of moisture, contamination, or carbonized marks

- Terminal quality and connection tightness

If the insulation resistance is unstable, replacement is recommended to prevent operational risk.

Step 5: Temperature and Operation Monitoring During Runtime

For installed capacitors, thermal monitoring is useful because overheating is often associated with:

- Excessive ambient heat

- Overvoltage conditions

- Internal component failure

Maintenance teams usually record operating temperature during scheduled inspections. When a capacitor shows abnormal heat patterns, testing and isolation should be performed immediately.

Key Signals that Indicate Replacement

Testing sometimes reveals that the capacitor is near its operational end. Indicators include:

- Non-recoverable swelling of the metal case

- Noticeable decrease in capacitance

- High insulation leakage

- Frequent triggering of capacitor switches or controllers

Capacitor replacement is not only a troubleshooting action but an investment in system reliability.

Testing in a B2B Procurement and Maintenance Strategy

B2B buyers typically consider long-term stability and total lifecycle cost instead of simple upfront pricing. Testing procedures allow purchasing departments to evaluate the technical capability of suppliers. Well-tested capacitors ensure:

- Lower risk of breakdown

- Less reactive power loss

- Higher equipment lifespan

In cross-regional B2B trade, such as distribution to power grid contractors or industrial panel builders, power capacitors are often shipped in large quantities. Inspecting samples during inbound QC reduces return costs and delays.

B2B Checklist for Evaluating Tested Power Capacitors

| Evaluation Item | Benefit for Business Operations |

| Visual Inspection | Prevents early-stage failure in capacitor banks |

| Capacitance Testing | Ensures stable power factor correction |

| Insulation Resistance Check | Avoids shutdown and overheating risks |

| Vendor Quality Certification | Reduces procurement risks and replacement frequency |

Good testing practices enhance both system safety and operational profitability.

Conclusion

Testing a power capacitor is not only a technical procedure but also a power system management strategy. For facilities requiring continuous power quality control—especially those using reactive power compensation cabinets and capacitor banks—regular inspection helps prevent downtime and enables predictable maintenance planning. A structured testing approach ensures:

- Safety and performance consistency

- Long service life of electrical equipment

- Improved power factor and minimized inefficiencies

With appropriate testing and vendor evaluation, industrial buyers and engineering teams can maintain stable and efficient electrical systems with confidence.